Custom Metal Fabrication in Coral Gables, FL

For custom metal fabrication coral gables, we support contractors, builders, and project teams with job-ready parts and clean documentation. Serving Coral Gables and nearby markets like Miami, Coconut Grove, Brickell, South Miami, Kendall, Doral, Miami Beach, Key Biscayne, Hialeah, Miami Springs, North Miami, Fort Lauderdale, and West Palm Beach.

Schedule Inspection

The highest quality metals and materials.

Fabrication documentation

that stays job-ready

Coastal projects move faster when details fit clean and references are easy to verify. For custom metal fabrication coral gables, we keep drawings, cut lists, and part notes organized so teams can coordinate trims, flashings, brackets, plates, and specialty transitions with fewer delays across Coral Gables and the Miami area.

Parts that match the scope

Cut lists, dimensions, and edge notes aligned so installs fit cleaner and field adjustments drop.

References you can verify

Key references are easy to confirm so teams can reduce rework and keep approvals moving.

Support across South Florida

From Coral Gables to surrounding markets, we help keep documentation consistent from start to closeout.

Certification gallery

Signals that help reduce risk, support compliance, and speed up approvals across Florida projects.

Our Services

For custom metal fabrication coral gables, we help teams coordinate job-ready parts and related materials. Common scopes include custom trims and flashings, brackets and plates, specialty transitions, and packaging that supports cleaner installs. Many projects also bundle roofing panels, soffit/fascia, structural metal deck, and hardware for a complete order.

5V Crimp Metal Roofing

Roofing panels that often pair with fabricated trims, flashings, and specialty transitions.

- Finish and gauge options aligned to scope.

- Accessory coordination for cleaner detailing.

Low Slope / Flat Roof Metal Systems

Commercial systems that often require custom edges, curbs, scuppers, and transition parts.

- Guidance for edges, terminations, and transitions.

- Submittal-ready documentation for approvals.

B-Decking / Structural Metal Deck

Structural decking supply support that can pair with fabricated plates, angles, and connection parts.

- Profiles and material options aligned to scope.

- Documentation support for engineering review.

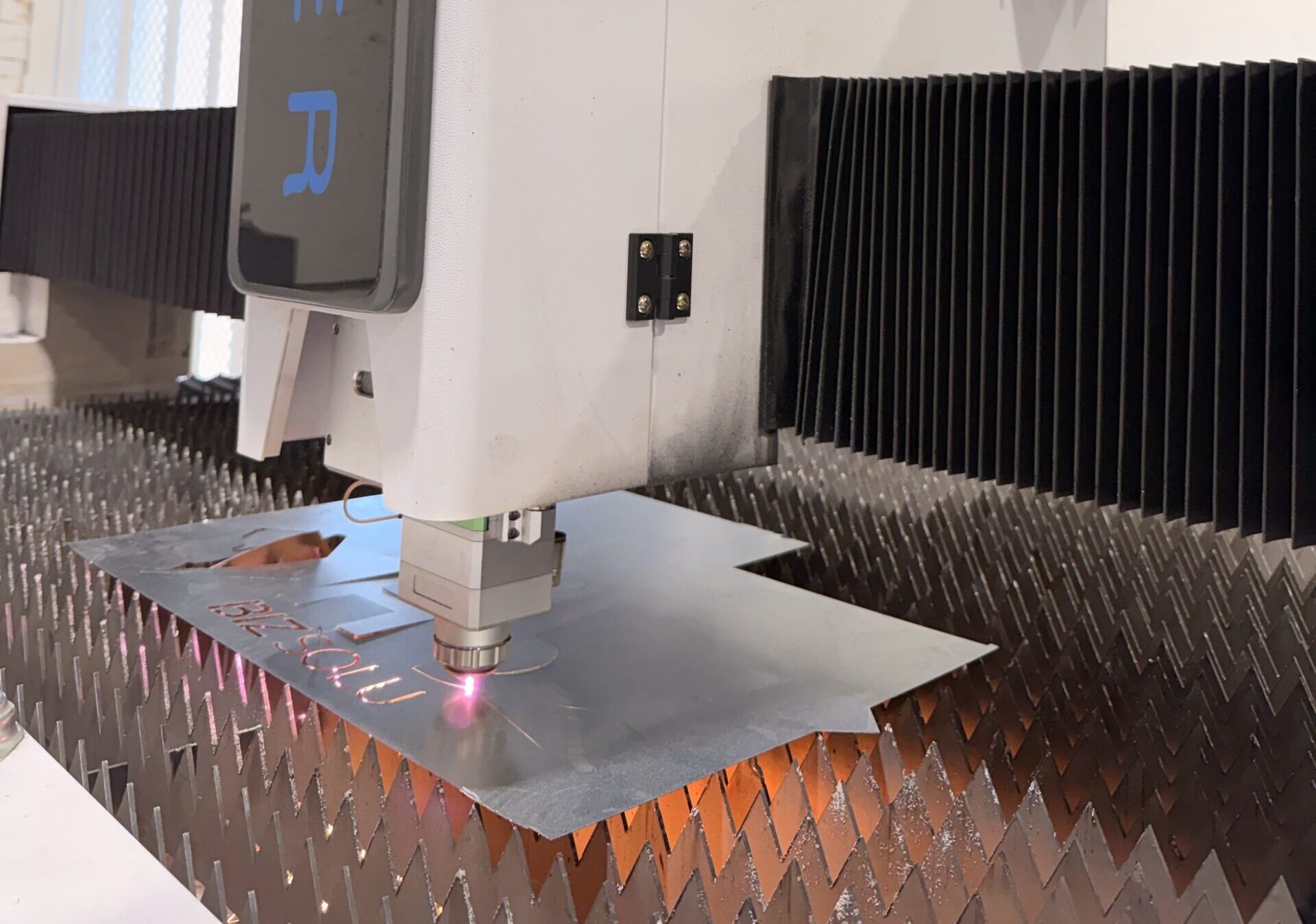

Laser Cutting & Custom Fabrication

Custom metal fabrication coral gables support for trims, brackets, plates, and specialty details built to match drawings.

- Parts built to match dimensions and tolerances.

- Cleaner installs with less field adjustment.

Roof Installation – Homeowners

Homeowner support for selecting the right system and coordinating trims and accessory details.

- Help selecting profiles, finishes, and scope basics.

- Clear delivery coordination and staging.

Metal Soffit Systems

Soffit and fascia options that often need custom transitions and finish matching for cleaner exteriors.

- Vented or solid options aligned to scope.

- Accessory coordination for a uniform finish.

PROJECT SUPPORT WORKFLOW

For custom metal fabrication coral gables, we keep documentation clean and the part package aligned. Identify the need, verify requirements, assemble a project-ready packet, and deliver with fewer delays across Coral Gables and nearby markets like Miami, Coconut Grove, Brickell, South Miami, Kendall, Doral, Miami Beach, and North Miami.

Identify

Select part type, material, finish, and edge notes so documentation matches the scope and detailing stays aligned.

Verify

Confirm references needed for the job, including coastal and wind-related requirements when applicable.

Assemble

Compile cut lists, part notes, and coordination references—plus related details for trims, flashings, hardware, and transitions.

Deliver

Send a clean, project-ready packet that reduces back-and-forth and keeps installs moving.

FABRICATION

Precision fabrication built for clean fit and faster installation

Custom Metal Fabrication Coral Gables to custom components, our fabrication workflow keeps tolerances controlled and output job ready. You get parts that align cleanly, reduce on site adjustments, and support a sharper final finish.